3D Printing

Our state-of-the-art on-site prototyping and manufacturing facilities combined with our knowledge and experience in plastics allow us to streamline the product development process by quickly producing fully functional and aesthetical models to garner feedback, test, iterate and improve.

MJF 3D Printing

At the Applied Polymer Technologies Gateway in Tus Athlone, we elevate your design possibilities with our state-of-the-art cutting-edge 3D printing capabilities featuring the HP Multi Jet Fusion 5200 series.

This advanced printer offers an effective building volume of 380 x 284 x 380 mm and utilizes voxel-level technology, which allows for precise control over the properties of each individual pixel—enabling the creation of parts with tailored isotropic characteristics that enhance strength and flexibility.

Our facility supports a diverse range of high-performance materials, including Polypropylene (PP), PA11, PA12 (Nylon), and elastomers, making it ideal for various end-use applications such as robust prototypes, functional components, and specialized parts in demanding industries. Discover how our state-of-the-art technology can transform your projects and meet your specific needs effectively.

SLA 3D Printing

SLA is all about precision and accuracy, so it is often used when form, fit, and assembly are critical. The tolerances on SLA parts are typically less than 0.05 mm, and SLA offers the smoothest surface finish of any additive manufacturing process. With the quality SLA can achieve, it is particularly useful for creating highly precise casting patterns (e.g., for injection moulding, casting, and vacuum casting) as well as functional prototypes, presentation models, and form and fit testing. SLA technology is extremely versatile and can be used in any number of areas where precision is paramount.

Our Gold Standard industrial ProJet 6000 HD SLA 3D printer has unmatched capabilities of Stereolithography 3D printing technology, this is an industrial machine fine-tuned for cost-efficiency and unrivalled material availability. 3D Print SLA parts with highest quality of accuracy and surface finish.

We have a range of Formlabs desktop 3d printers to utilise a wide variety of formulation configurations with a fast turnaround: materials can be soft or hard, imbued with mechanical properties, mixed and matched to suit your prototyping needs.

FDM 3D Printing

Fused deposition modeling (FDM) is the most widely used form of 3D printing at the consumer level. Our range of FDM 3D printers allow us to build everything from large parts up to 600mm cubed to composites based on your needs.

Our flagship Composite Base material — is a micro carbon fiber filled nylon that yields accurate parts with near flawless surface finish. Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts. Today, there are more than a million Onyx parts in the field transforming manufacturing.

Prototyping, production tooling, and manufacturing processes are all simplified with industrial additive manufacturing technology. Add large-format 3D printers into your process workflows to reduce production costs and time-to-market, and develop sustainable practices that enable complete control throughout your product's entire life cycle.

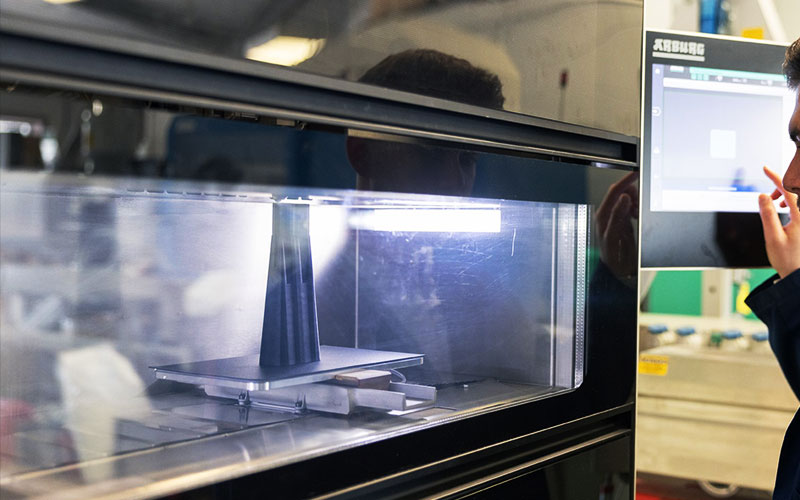

The Arburg Freeformer

The Arburg Freeformer is an industrial 3D printer made by ARBURG additive, a manufacturer from Germany. One of its distinctive features is that it’s a pellet 3D printer: the materials used by the freeformer are plastic pellets, also called plastic granulates.

This 3D printer is capable of 3D printing objects without support structures, layer by layer from minuscule droplets. The discharge unit with nozzle remains stationary, while the component carrier moves on three or five axes. Depositing drops of liquid plastic to build up parts, layer by layer, the freeformer has a patented nozzle that opens and closes up to 100 times a second.

This 3D printing technology is close to the ProJet technology by 3D Systems and is close to the approach chosen by HP for their line of industrial-grade 3D printers. ARBURGadditive named this new 3D printing technology the additive ARBURG Plastic Freeforming (APF) process and introduces the freeformer as an alternative to injection moulding.

GOM 3D Scanning

Optical Metrology for the Plastics Industry

3D scanning is the process of analyzing a real-world object or environment to collect extremely accurate data on its shape and appearance. The collected data can then be used to construct digital 3D models, compare surface analysis, reverse engineer components or analysis defects on parts such as surface roughness, sink, or draft. GOM 3D Scanning is a type of digital photogrammetry that is ideal for a variety of use cases requiring fast dimensional inspection and precise measurement data. In manufacturing, 3D scanning is used as a type of quality control and coordinate measuring system.

Specs:

• Working range: 0.25 - 0.25m

• Scanning area: 200 × 150 mm

• Technology: Structured light

• Output formats: STL

3D printing filament

The APT centre offers two different options for the production of filament for use in 3D printing. The 3devo Composer 450 lab-based filament production line consists of an interchangeable mixing screw which is suitable for the production of small quantities (<1Kg) of FDM filament from 0.5 to 3mm diameter at a max temperature of 450C allowing it to produce filament from engineering polymers such as PEEK. For larger batches of filament, a fully integrated filament production line with laser micrometer control of the filament to ensure high-quality filament is produced. The line is equipped with automatic spool changing/cutting and is capable of producing filaments from a range of thermoplastic resins at a rate of up to 12Kgs per hour.

Equipment

- ARBURG Freeformer, high temperature enabled

- Formlabs 2

- 3D Scanner (GOM)

- ProJet 6000 HD SLA 3D printer

- Large-format FDM 3D printer

If you require further advice on tensile properties testing please fill in the form below