PRISM/APT researchers have partnered with an international team of experts to investigate the reusable polymer packaging (BUDDIE-PACK project). The European project BUDDIE-PACK, funded by the new Horizon Europe programme, brings together prominent academia and industry experts, including 19 partners from 6 different countries. Its aim is to implement a comprehensive approach for the large-scale development of reusable plastic packaging (RPP).

The project's primary focus is on developing innovative packaging materials as well as cleaning solutions to ensure consumer safety by addressing potential contamination and aging of RPP during repeated use. Additionally, it aims to enhance the durability of RPP's functional properties to prevent food spoilage. BUDDIE-PACK will have a significant impact by significantly reducing the production of single-use plastic packaging, minimizing water and energy consumption, and preventing the release of microplastics into the oceans.

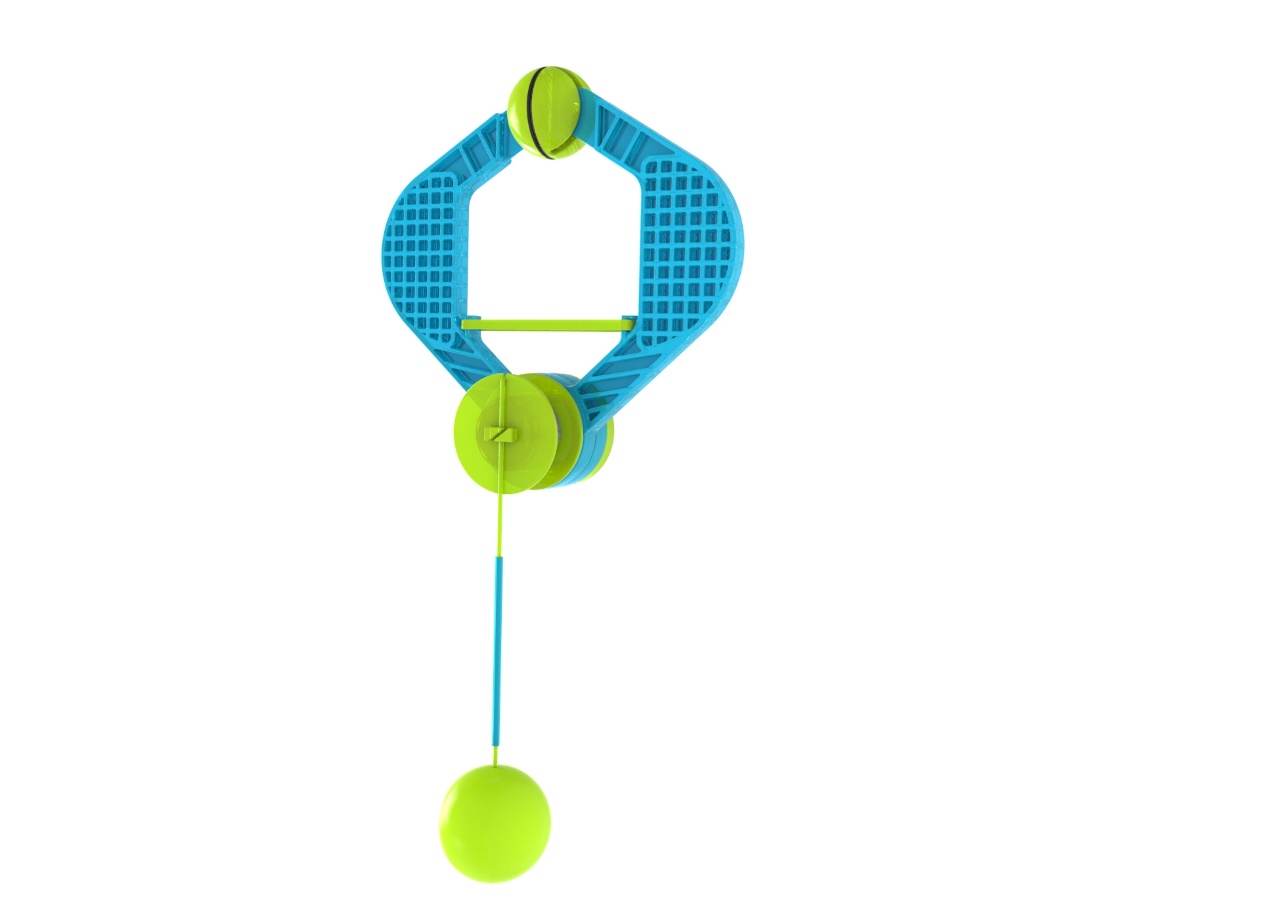

nitially, Sandy Sports noticed early in their research stage there was a large gap in the market of suitable toys for children as young as two years of age to engage with safely. Sourcing and testing multiple toys on the market Sandy Sports were not satisfied there was a product that met this need. AIT, were tasked with incorporating the features Sandy sports felt best developed hand-eye coordination and motor skills into a toy suitable for children as young as two years of age. From day one, Sandys Sports priority was to develop a safe environment for a child to develop skills while playing and learning.

AIT firstly carried out a large background research stage into safety features, a report was drafted for the stakeholders outlining suitable materials and suggesting features which would prevent harm and choking without effecting the functionality of the toy. Once agreed, AIT developed 6 early stage concepts of the products. A concept was selected by the stakeholder to be refined in CAD. Dimensional drawings were then supplied to Sandy Sports for approval before prototyping commenced. The prototyping stage was an iterative process.

Final deliverables included:

Report on suitable materials and safety mechanisms.

Two functional full scale models for usability testing

Renders of the models in a variety of colours

2D production drawings

2D patent drawings

3D universal step. Files to production costings

CISD feel the real innovation in this project was delivered in the CAD design. The initial design developed in voucher 1 satisfied all the needs of the stakeholder in terms of safety and functionality. However, this design included over 15 separate injection moulding parts, making tooling unaffordable to the start up. In the second voucher, clever design reduced the number of parts to 7 and removed the need for ultrasonic welding considerably reducing the cost of production without compromising safety or functionality.

By levering AIT’s expertise in polymer design, materials and injection moulding, Sandy Sports were able to develop a feasible innovative children’s educational toy to test on the market. The process was a steep learning curve into product design and polymer manufacturing. Intellectual property drawings were used to protect the product while renders can be used to build interest, market the toy and gain further investment.

"I am at the start up stage and have been working with Gavin for the past 18 months. Through the local enterprise I was able to connect with Gavin. We had an idea and needed his expertise to bring it to real life! After two innovation vouchers we had a finished prototype with a completely new design.

The journey was a great experience. Gavin was always very helpful, understanding and professional throughout the project. He provided me with a lot of necessary guidance and support. The knowledge I have come away with is invaluable. Whenever I had a question, whether via email or phone, he made himself available.

Credit to Gavin and his team. They were an absolute pleasure to work with. No doubt we will meet again at some point in the future!

"

Alec Sandys