Design Case Study

Development of child’s educational toy

Company Name: Sandy Sports ltd

Funding Source & Value: 2 x 5k innovation vouchers

Profile of Company:

Sandy Sports ltd is a start-up company with a strong focus on developing children’s educational toys. Alec a tennis enthusiast, wanted to develop a toy with the aim to improve hand-eye coordination and motor skills for children aged 3 years and over.

Problem to Be Solved

Initially, Sandy Sports noticed early in their research stage there was a large gap in the market of suitable toys for children as young as two years of age to engage with safely. Sourcing and testing multiple toys on the market Sandy Sports were not satisfied there was a product that met this need. AIT, were tasked with incorporating the features Sandy sports felt best developed hand-eye coordination and motor skills into a toy suitable for children as young as two years of age. From day one, Sandys Sports priority was to develop a safe environment for a child to develop skills while playing and learning.

How APT Delivered a Solution:

APT first carried out a large background research stage into safety features, a report was drafted for the stakeholders outlining suitable materials and suggesting features which would prevent harm and choking without effecting the functionality of the toy. Once agreed, upon, APT developed 6 early stage concepts of the products. A concept was selected by the stakeholder to be refined in CAD. Dimensional drawings were then supplied to Sandy Sports for approval before prototyping commenced. The prototyping stage was an iterative process.

How APT Delivered a Solution:

Final deliverables included:

1 Report on suitable materials and safety mechanisms.

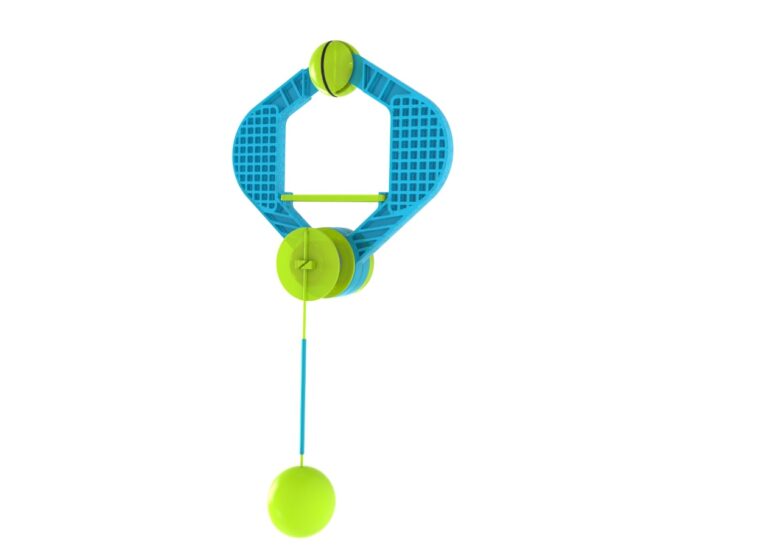

2.Two functfull-scale scale models for usability testing

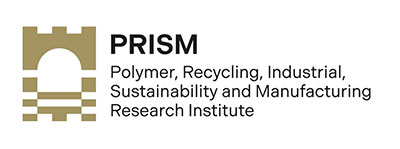

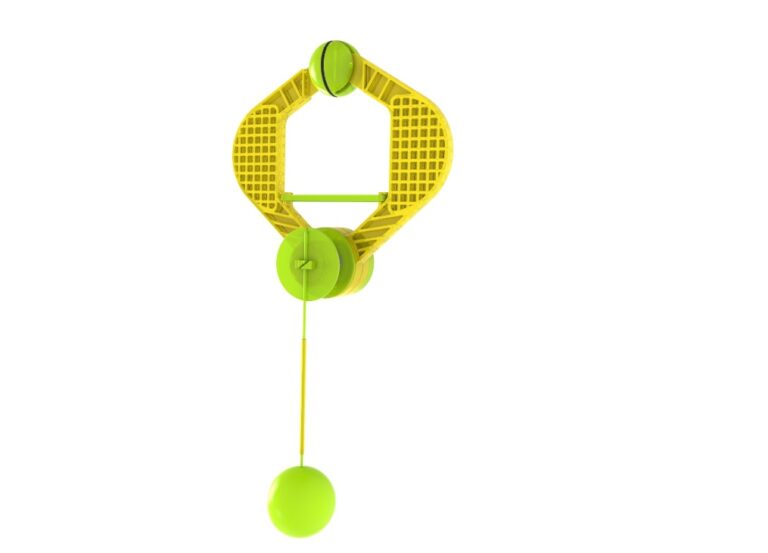

3 .Renders of the models in a variety of colours

4. 2D production drawings

5. 2D patent drawings

6. 3D universal step.

Impact for the Company

CISD feel the real innovation in this project was delivered in the CAD design. The initial design developed in voucher one satisfied all the needs of the stakeholder in terms of safety and functionality. However, this design included over 15 separate injection moulding parts, making tooling unaffordable to the start up. In the second voucher, clever design reduced the number of parts to seven and removed the need for ultrasonic welding considerably reducing the cost of production without compromising safety or functionality.

Company Testimonial

By levering APT'S expertise in polymer design, materials and injection moulding, Sandy Sports were able to develop a feasible innovative children’s educational toy to test on the market. The process was a steep learning curve in product design and polymer manufacturing. Intellectual property drawings were used to protect the product while renders can be used to build interest, market the toy and gain further investment.