Design Case Study

Development of Electronics Enclosure

Company Name: Dickson Agri Solutions ltd

Funding Source & Value: 2 x 5k innovation vouchers

Profile of Company:

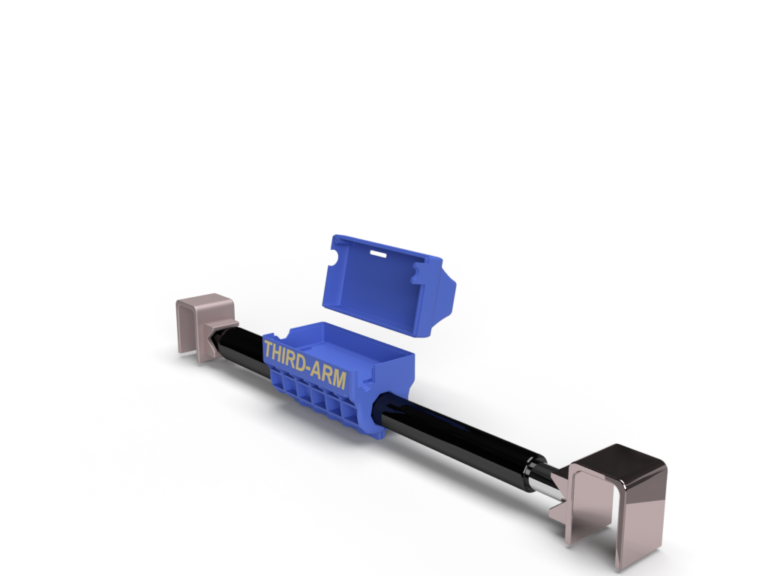

Dickson Agri Solutions ltd is a start-up company set up by Philip Dickson. The Third Arm is a new device invented by Phillip a Farmer & Mechanic, the unit attaches to the link arms of a tractor and allows the operator to safely and remotely move in and out the arms of the tractor while attaching an implement. Philip thought of the idea originally to aid his father and allow him to attach and detach implements safely while Philip worked off farm. The Third Arm has many benefits Safety being one of the most paramount as the device allows the user to operate the Third Arm while being inside the cab of the tractor it removes the risk or need for the operator to enter the crush zone between tractor and implement while attaching an implement. With over 214 fatal accidents in the last 10 years on Irish farms The Third Arm was seen as invaluable device and presented the possibility of potentially saving a life or otherwise removing what was once a dangerous and time-consuming task.

Problem to Be Solved

Dickson Agri solutions approached CISD with an Innovation Voucher looking to get design work done for their new product the Third Arm. The Third Arm required a plastic enclosure to house the required electronics in a sleek and affective way. Philip wanted a housing that would attach to the body of the Third Arm & would allow the user to effectively and easily move the unit around.

How CISD Delivered a Solution for Dickson Agri Solutions:

Working alongside Philip CISD developed an enclosure that would encapsulate the electronics required while also attaining the various other functions that were required of the part.

Impact for the Company

By utilising the Innovation Vouchers available through Enterprise Ireland, Dickson Agri Solutions were able to develop design and test fully functional prototypes through CISD. This has helped the company along their journey to getting their product the Third ARM to market.

Company Testimonial

I am a start up business in the agricultural sector. I began working with CISD over a year ago and can honestly say without their help and guidance I could not have progressed as far as I am today. I am now looking at the early days of production for my innovation the third arm. Cathal and his expertise have been forefront in helping me get to this exciting stage. There professionalism and support has without a doubt got me to this position. I am positive because of there work and commitment my business will be a resounding success and I will continue to work with them in future.

Regards Philip Dickson

Dickson Agri solutions